Difference between revisions of "PIC16F877A PWM"

| (31 intermediate revisions by the same user not shown) | |||

| Line 10: | Line 10: | ||

*16 bit Capture Register | *16 bit Capture Register | ||

*16 bit Compare Register | *16 bit Compare Register | ||

| − | *10-bit PWM | + | *10-bit PWM Register. |

In this tutorial we will be discussing only the PWM part of CCP. PIC has 2PWM module with a resolution of 10-bits. | In this tutorial we will be discussing only the PWM part of CCP. PIC has 2PWM module with a resolution of 10-bits. | ||

| Line 18: | Line 18: | ||

{| class="table table-striped table-hover table-condensed table-bordered" | {| class="table table-striped table-hover table-condensed table-bordered" | ||

|-class="info" | |-class="info" | ||

| − | !PWM Channel || Port Pin || Control Register || Duty Cycle Register | + | !PWM Channel || Port Pin || Control Register || Duty Cycle Register || Period Register |

|- | |- | ||

| − | |PWM1|| PC.2 || CCP1CON || CCPR1L | + | |PWM1|| PC.2 || CCP1CON || CCPR1L || PR2 |

|- | |- | ||

| − | |PWM2|| PC.1 || CCP2CON || CCPR2L | + | |PWM2|| PC.1 || CCP2CON || CCPR2L || PR2 |

| − | |} | + | |}<br><br> |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | =PWM Working= | ||

| − | + | Before going to the PIC PWM module lets understand few terminologies wrt below image:<br><br> | |

| − | + | [[FILE:Pwm.png]] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | <b>Ton:</b> Time for which the signal is ON/HIGH.<br> | |

| − | + | <b>Toff:</b> Time for which the signal is OFF/LOW.<br> | |

| − | + | <b> Period:</b> The cycle time of the signal which is nothing but the sum of Ton and Toff period.<br> | |

| − | 1 | + | Period= Ton+Toff<br> |

| + | Freq of Pwm signal = 1/Period.<br> | ||

| − | + | <b>Duty Cycle:</b> The percentage of time for which the PWM signal will be ON/HIGH. | |

| − | + | $$DutyCycle = (Ton/(Ton+Toff))*100 = (Ton/Period) * 100 $$ | |

| − | + | <br><br> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | Below diagram shows the PIC16f877a PWM block diagram and output signal generation. | |

| − | + | [[FILE:Pic16f877a_Pwm.png]]<br> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | PIC uses TIMER2 for generating the PWM signals. Lets relate the above concepts with the PIC registers.<br> | |

| − | + | <b>Period:</b>PR2 register is used to specify the PWM Period. The PWM period can be calculated using the following formula. | |

| − | + | $$PWM Period = [(PR2) + 1] * 4 * TOSC * (TMR2 Prescale Value)$$ | |

| − | 1 | + | |

| − | + | <b>DutyCycle:</b>CCPR1L and CCP1CON<5:4> are used to specify the DutyCycle.The CCPR1L contains the eight MSbs and the CCP1CON<5:4> contains the two LSbs. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| + | <b>PWM Signal Generation:</b> Once the PWM is configured and Timer2 is enabled, TMR2 starts incrementing depending on the prescalar. | ||

| + | Once the <b>TMR2</b> value is equal to dutyCycle<b>(CCPR1L+CCP1CON<5:4>)</b> the PWM pin will be pulled LOW. The timer still continues to increment till it matches with the period <b>PR2</b>. After which the PWM pin will be pulled HIGH and TMR2 is reset for next cycle. | ||

| + | <br><br><br><br> | ||

| + | =PIC16F877A PWM Registers= | ||

| + | The below table shows the registers associated with PIC16F877A PWM.<br> | ||

{| class="table table-striped table-hover table-condensed table-bordered" | {| class="table table-striped table-hover table-condensed table-bordered" | ||

|-class="info" | |-class="info" | ||

| − | ! | + | !Register || Description |

|- | |- | ||

| − | | | + | |CCPxCON|| This register is used to Configure the CCP module for Capture/Compare/PWM opertaion. |

| − | |- | + | |- |

| − | | | + | |CCPRxL|| This register holds the 8-Msb bits of PWM, lower 2-bits will be part of CCPxCON register. |

| − | + | |- | |

| − | + | |TMR2|| Free running counter which will be compared with CCPR1L and PR2 for generating the PWM output. | |

| − | + | |}<br><br> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | <br><br> | + | |

| − | + | ||

| + | =Register Configuration= | ||

| + | The below table shows the registers associated with PIC16f877a PWM.<br> | ||

{| class="table table-striped table-hover table-condensed table-bordered" | {| class="table table-striped table-hover table-condensed table-bordered" | ||

|-class="info" | |-class="info" | ||

| − | + | |CCPxCON | |

|- | |- | ||

| − | | | + | |7 || 6 || 5 || 4 || 3 || 2 || 1 || 0 |

| − | |- | + | |- |

| − | | | + | |— || — || CCPxX || CCPxY || CCPxM3 || CCPxM2 || CCPxM1 || CCPxM0 |

|} | |} | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | <b>CCPxX:CCPxY:</b> PWM Least Significant bits<br> | |

| − | + | These bits are the two LSbs of the PWM duty cycle. The eight MSbs are found in CCPRxL. | |

| − | + | <b>CCPxM3:CCPxM0:</b> CCPx Mode Select bits<br> | |

| − | + | 0000 - Capture/Compare/PWM disabled (resets CCPx module)<br> | |

| − | + | 0100 - Capture mode, every falling edge<br> | |

| − | + | 0101 - Capture mode, every rising edge<br> | |

| − | + | 0110 - Capture mode, every 4th rising edge<br> | |

| − | + | 0111 - Capture mode, every 16th rising edge<br> | |

| − | <br><br> | + | 1000 - Compare mode, set output on match (CCPxIF bit is set)<br> |

| − | + | 1001 - Compare mode, clear output on match (CCPxIF bit is set)<br> | |

| − | + | 1010 - Compare mode, generate software interrupt on match (CCPxIF bit is set, CCPx pin is unaffected)<br> | |

| − | + | 1011 - Compare mode, trigger special event (CCPxIF bit is set, CCPx pin is unaffected);<br> | |

| − | + | <b>11xx - PWM mode</b> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

<br><br> | <br><br> | ||

=Steps to Configure PWM= | =Steps to Configure PWM= | ||

| − | #Configure the | + | #Configure the CCP1 module for PWM operation. |

| − | # | + | #Set the PWM period by writing to the PR2 register. |

| − | #Set the | + | #Set the PWM duty cycle by writing to the CCPR1L register and CCP1CON<5:4> bits. |

| − | + | #Make the CCP1 pin an output by clearing the TRISC<2> bit. | |

| − | # | + | #Set the TMR2 prescale value and enable Timer2 by writing to T2CON. |

| − | + | ||

| − | # | + | |

| − | + | ||

<br><br> | <br><br> | ||

| − | = | + | =Code= |

| − | Program to demonstrates the | + | Program to demonstrates the LED fading using PWM signals. |

| − | + | ||

| − | + | ||

<html> | <html> | ||

| − | <script src="https://gist.github.com/SaheblalBagwan/ | + | <script src="https://gist.github.com/SaheblalBagwan/2d9ab8cbf840407b7248fef40fc56e21.js"></script> |

</html> | </html> | ||

| − | <br><br><br> | + | <br> |

| + | |||

| + | |||

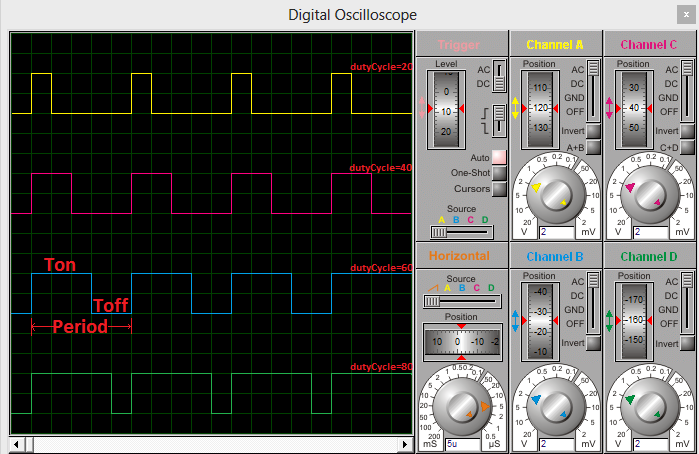

| + | =Using ExploreEmbedded Libraries= | ||

| + | Progarm to generate the PWM signals of 25% & 75% duty cycle using explore embedded libraries. | ||

| + | <html> | ||

| + | <script src="https://gist.github.com/SaheblalBagwan/5a49f953cd43f136fe954777c4373128.js"></script> | ||

| + | </html> | ||

| + | |||

| + | Ouptut measured using CRO: | ||

| + | [[FILE:PwmOutput.png]] | ||

| + | <br><br> | ||

| + | |||

| + | =Downloads= | ||

| + | Download the complete project folder from the below link:<br> | ||

| + | [https://github.com/ExploreEmbedded/Pic16f877a_ExploreUltraPicDevKit/archive/master.zip Hardware design Files and Code Library] | ||

| + | |||

| + | |||

| + | Have a opinion, suggestion , question or feedback about the article let it out here! | ||

| + | {{DISQUS}} | ||

Latest revision as of 13:02, 27 July 2016

In this tutorial we are going to discuss the PWM module of PIC16F877A.

First we will see how to configure the PWM registers to generate signals of required PWM, At the end we will see how to use the ExploreEmdedded PWM library.

Contents

PIC16F877A PWM Module

PIC16F877A microcontroller has two independent CCP(Capture/Compare/PWM) modules, named as CCP1 and CCP2. Each CCP module has two 8-bit resistors(CCPxH,CCPxL) that can be use as:

- 16 bit Capture Register

- 16 bit Compare Register

- 10-bit PWM Register.

In this tutorial we will be discussing only the PWM part of CCP. PIC has 2PWM module with a resolution of 10-bits. The 8-Msb bits are stored in CCPRxL and remeining 2-bits in CCPxCON register. Below tables shows the PWM module of PIC.

| PWM Channel | Port Pin | Control Register | Duty Cycle Register | Period Register |

|---|---|---|---|---|

| PWM1 | PC.2 | CCP1CON | CCPR1L | PR2 |

| PWM2 | PC.1 | CCP2CON | CCPR2L | PR2 |

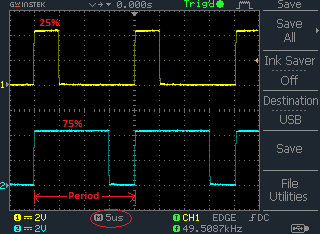

PWM Working

Before going to the PIC PWM module lets understand few terminologies wrt below image:

Ton: Time for which the signal is ON/HIGH.

Toff: Time for which the signal is OFF/LOW.

Period: The cycle time of the signal which is nothing but the sum of Ton and Toff period.

Period= Ton+Toff

Freq of Pwm signal = 1/Period.

Duty Cycle: The percentage of time for which the PWM signal will be ON/HIGH.

$$DutyCycle = (Ton/(Ton+Toff))*100 = (Ton/Period) * 100 $$

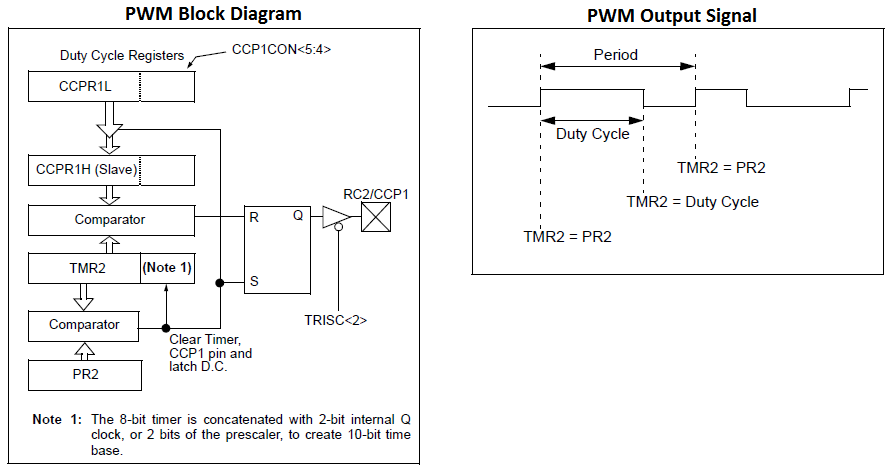

Below diagram shows the PIC16f877a PWM block diagram and output signal generation.

PIC uses TIMER2 for generating the PWM signals. Lets relate the above concepts with the PIC registers.

Period:PR2 register is used to specify the PWM Period. The PWM period can be calculated using the following formula.

$$PWM Period = [(PR2) + 1] * 4 * TOSC * (TMR2 Prescale Value)$$

DutyCycle:CCPR1L and CCP1CON<5:4> are used to specify the DutyCycle.The CCPR1L contains the eight MSbs and the CCP1CON<5:4> contains the two LSbs.

PWM Signal Generation: Once the PWM is configured and Timer2 is enabled, TMR2 starts incrementing depending on the prescalar.

Once the TMR2 value is equal to dutyCycle(CCPR1L+CCP1CON<5:4>) the PWM pin will be pulled LOW. The timer still continues to increment till it matches with the period PR2. After which the PWM pin will be pulled HIGH and TMR2 is reset for next cycle.

PIC16F877A PWM Registers

The below table shows the registers associated with PIC16F877A PWM.

| Register | Description |

|---|---|

| CCPxCON | This register is used to Configure the CCP module for Capture/Compare/PWM opertaion. |

| CCPRxL | This register holds the 8-Msb bits of PWM, lower 2-bits will be part of CCPxCON register. |

| TMR2 | Free running counter which will be compared with CCPR1L and PR2 for generating the PWM output. |

Register Configuration

The below table shows the registers associated with PIC16f877a PWM.

| CCPxCON | |||||||

| 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 |

| — | — | CCPxX | CCPxY | CCPxM3 | CCPxM2 | CCPxM1 | CCPxM0 |

CCPxX:CCPxY: PWM Least Significant bits

These bits are the two LSbs of the PWM duty cycle. The eight MSbs are found in CCPRxL.

CCPxM3:CCPxM0: CCPx Mode Select bits

0000 - Capture/Compare/PWM disabled (resets CCPx module)

0100 - Capture mode, every falling edge

0101 - Capture mode, every rising edge

0110 - Capture mode, every 4th rising edge

0111 - Capture mode, every 16th rising edge

1000 - Compare mode, set output on match (CCPxIF bit is set)

1001 - Compare mode, clear output on match (CCPxIF bit is set)

1010 - Compare mode, generate software interrupt on match (CCPxIF bit is set, CCPx pin is unaffected)

1011 - Compare mode, trigger special event (CCPxIF bit is set, CCPx pin is unaffected);

11xx - PWM mode

Steps to Configure PWM

- Configure the CCP1 module for PWM operation.

- Set the PWM period by writing to the PR2 register.

- Set the PWM duty cycle by writing to the CCPR1L register and CCP1CON<5:4> bits.

- Make the CCP1 pin an output by clearing the TRISC<2> bit.

- Set the TMR2 prescale value and enable Timer2 by writing to T2CON.

Code

Program to demonstrates the LED fading using PWM signals.

Using ExploreEmbedded Libraries

Progarm to generate the PWM signals of 25% & 75% duty cycle using explore embedded libraries.

Downloads

Download the complete project folder from the below link:

Hardware design Files and Code Library

Have a opinion, suggestion , question or feedback about the article let it out here!