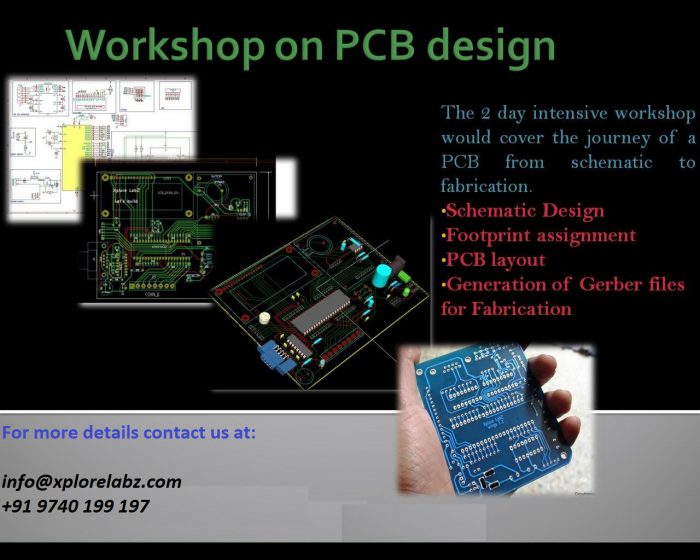

Workshop on PCB Design and Fabrication

The two day workshop would cover the following topics:<br\>

Contents

Need for PCB.

Printed Circuit Boards are essential part of electronics; they provide a convenient way to rig up circuits and test them. Not only they ease prototyping they enhance reliability of the products. The bread boarding techniques do not quite work if the number of connects increase substantially. Hence even for Hobby users PCB design is becoming essential. Also with smaller packaging sizes for Integrated circuits it is almost impossible to prototype on Breadboard. PCB designing can be very joyful, and intricate. They say it is more of an art then science. Lots of scope for the designer. So Let's build a few of them.

Introduction to KICAD.

A simple example: Schematic entry to PCB layout.

Schematic Entry in detail:

- Creating custom components.

- Importing standard libraries.

- Tools for creating components.

Generating Net list from schematic:

- Annotation schemes.

- Matching schematic symbols to footprints.

Footprints:

- Component packages.

- Measurement units & standards.

- Library footprints.

- Importing footprints.

- Creating custom footprints.

- Tools for footprint generation.

Board layout:

- Importing Net list.

- Footprint layout & form factor.

- Layers of design.

- Single layer, multilayer designs.

- Manual routing

- Custom Tracks & vias.

- Track width calculation.

- Auto Routing

- Outline routing tools.

- Generating custom routes.

Gerber file generation:

- Finalizing the design.

- Gerber file format for different layers.

- Appending multiple boards.

PCB Fabrication:

- Quick Presentation on PCB fabrication

- Checking FAB requirements.