Contents

Objective

In this tutorial we are going to discuss the serial communication using UART. For more info on UART/RS232 check 8051 tutorial.

LPC1768 has four inbuilt USARTs. We are going to discuss only UART0. After this tutorial you should be able to extend it to remaining three UARTS.

After understating the basics of LPC1768 UART module, We will discuss how to use the ExploreEmbedded libraries to communicate with any of the UART devices.

UART module

UART module and registers.

LPC1768 has 4-UARTs numbering 0-3, similarly the pins are also named as RXD0-RXD3 and TXD0-TXD3.

As the LPC1768 pins are multiplexed for multiple functionalities, first they have to be configured as UART pins.

Below table shows the multiplexed UARTs pins.

| Port Pin | Pin Number | PINSEL_FUNC_0 | PINSEL_FUNC_1 | PINSEL_FUNC_2 | PINSEL_FUNC_3 |

|---|---|---|---|---|---|

| P0.02 | 98 | GPIO | TXD0 | ADC0[7] | |

| P0.03 | 99 | GPIO | RXD0 | ADC0[6] | |

| p2.00 | 75 | GPIO | PWM1[1] | TXD1 | |

| P2.01 | 74 | GPIO | PWM1[2] | RXD1 | |

| P0.10 | 48 | GPIO | TXD2 | SDA2 | MAT3[0] |

| P0.11 | 49 | GPIO | RXD2 | SCL2 | MAT3[1] |

| P4.28 | 82 | GPIO | RX_MCLK | MAT2[0] | TXD3 |

| P4.29 | 85 | GPIO | TX_MCLK | MAT2[1] | RXD3 |

UART Registers

The below table shows the registers associated with LPC1768 ADC.

We are going to focus only on ADCR and ADGDR as these are sufficient for simple A/D conversion.

However once you are familer with LPC1768 ADC, you can explore the other features and the associated registers.

| Register | Description |

|---|---|

| RBR | Contains the recently received Data |

| THR | Contains the data to be transmitted |

| FCR | FIFO Control Register |

| LCR | Controls the UART frame formatting(Number of Data Bits, Stop bits) |

| DLL | Least Significant Byte of the UART baud rate generator value. |

| DLM | Most Significant Byte of the UART baud rate generator value. |

UART Register Configuration

Now lets see how to configure the individual registers for UART communication.

ADCR ( ADC Control Register )

This registers contains the bits for channel selection, ADC conversion clock speed and Starting the conversion.

| ADCR | ||||||||

|---|---|---|---|---|---|---|---|---|

| 31:28 | 27 | 26:24 | 23:22 | 21 | 20:17 | 16 | 15:8 | 7:0 |

| Reserved | EDGE | START | Reserved | PDN | Reserved | BURST | CLCKDIV | SEL |

Bit 7:0 – SEL : Channel Select

These bits are used to select a particular channel for ADC conversion. One bit is allotted for each channel. Setting the Bit-0 will make the ADC to sample AD0[0] for conversion. Similary setting bit-7 will do the conversion for AD0[7].

Bit 15:8 – CLCKDIV : Clock Divisor

The APB clock (PCLK_ADC0) is divided by (this value plus one) to produce the clock for the A/D converter, which should be less than or equal to 13 MHz.

Bit 16 – BURST

This bit is used for BURST conversion. If this bit is set the ADC module will do the conversion for all the channels that are selected(SET) in SEL bits.

CLearing this bit will disable the BURST conversion.

Bit 21 – PDN : Power Down Mode

Setting this bit brings ADC out of power down mode and makes it operational.

Clearing this bit will power down the ADC.

Bit 24:26 – START

When the BURST bit is 0, these bits control whether and when an A/D conversion is started:

| Bit Value | FIFO Status |

|---|---|

| 000 | Conversion Stopped |

| 001 | Start Conversion Now |

The remaining cases (010 to 111) are about starting conversion on occurrence of edge on a particular CAP or MAT pin.

Bit 27 - EDGE

This bit is significant only when the START field contains 010-111.

It starts conversion on selected CAP or MAT input.

| Bit Value | Start Conversion |

|---|---|

| 0 | On Falling Edge |

| 1 | On Rising Edge |

ADGDR ( ADC Global Data Register )

| ADCR | ||||||||

|---|---|---|---|---|---|---|---|---|

| 31 | 27 | 26:24 | 23:16 | 15:4 | 3:0 | |||

| DONE | OVERRUN | CHN | Reserved | RESULT | Reserved | |||

Bit 15:4 - RESULT

This field contains the 12bit A/D conversion value for the selected channel in ADCR.SEL

The vale for this register should be read oncve the conversion is completed ie DONE bit is set.

Bit 26:24 - CHN : Channel

These bits contain the channel number for which the A/D conversion is done and the converted value is available in RESULT bits(e.g. 000 identifies channel 0, 011 channel 3...).

Bit 27 - OVERRUN

This bit is set during the BURST mode where the previous conversion data is overwritten by the new A/D conversion value.

Bit 31 - DONE

This bit is set to 1 when an A/D conversion completes. It is cleared when this register is read and when the ADCR is written. If the ADCR is written while a conversion is still in progress, this bit is set and a new conversion is started.

Some other registers

Though there are some more registers, we are restricting ourselves to use these registers only as this will be more convenient.

Apart from ADC Global Data register there are more 8 ADC Data registers (one Data register per ADC channel). DONE and OVERRUN bits for each channel can be monitored separately from the bits present in ADC Status register.

One can use the A/D Global Data Register to read all data from the ADC else use the A/D Channel Data Registers. It is important to use one method consistently because the DONE and OVERRUN flags can otherwise get out of synch between the AD0GDR and the A/D Channel Data Registers, potentially causing erroneous interrupts or DMA activity.

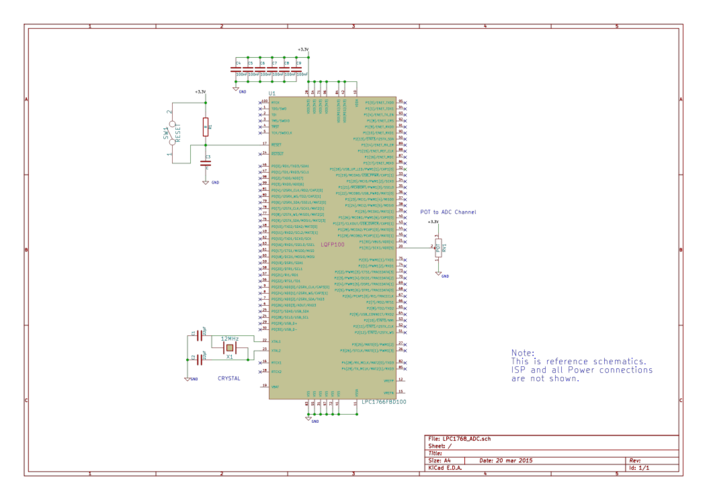

Schematic

Steps for Configuring and Using the Adc

Below are the steps for configuring the LPC1768 ADC.

- Step1: Configure the GPIO pin for ADC function using PINSEL register.

- Step2: Enable the CLock to ADC module.

- Step3: Deselect all the channels and Power on the internal ADC module by setting ADCR.PDN bit.

- Step4: Select the Particular channel for A/D conversion by setting the corresponding bits in ADCR.SEL

- Step5: Set the ADCR.START bit for starting the A/D conversion for selected channel.

- Step6: Wait for the conversion to complete, ADGR.DONE bit will be set once conversion is over.

- Step7: Read the 12-bit A/D value from ADGR.RESULT.

- Step8: Use it for further processing or just display on LCD.

Code

Here we are going to do the A/D conversion for only ADC[0]. The result of the A/D conversion will be displayed on the LCD.

#include<lpc17xx.h> #include "lcd.h" //ExploreEmbedded LCD library which contains the lcd routines #include "delay.h" //ExploreEmbedded delay library which contains the delay routines /* Bit positions of ADCR and ADGR registers */ #define SBIT_BURST 16u #define SBIT_START 24u #define SBIT_PDN 21u #define SBIT_EDGE 27u #define SBIT_DONE 31u #define SBIT_RESULT 4u #define SBIT_CLCKDIV 8u void main() { uint16_t adc_result; SystemInit(); //Clock and PLL configuration /* Setup/Map the controller pins for LCD operation RS RW EN D0 D1 D2 D3 D4 D5 D6 D7*/ LCD_SetUp(P2_0,P2_1,P2_2,P1_20,P1_21,P1_22,P1_23,P1_24,P1_25,P1_26,P1_27); /* Specify the LCD type(2x16) for initialization*/ LCD_Init(2,16); LPC_SC->PCONP |= (1 << 12); /* Enable CLOCK for internal ADC controller */ LPC_ADC->ADCR = ((1<<SBIT_PDN) | (10<<SBIT_CLCKDIV)); //Set the clock and Power ON ADC module LPC_PINCON->PINSEL1|= 0x01<<14; /* Select the P0_23 AD0[0] for ADC function */ while(1) { LPC_ADC->ADCR |= 0x01; /* Select Channel 0 by setting 0th bit of ADCR */ DELAY_us(10); /* allow the channel voltage to stabilize*/ util_BitSet(LPC_ADC->ADCR,SBIT_START); /*Start ADC conversion*/ while(util_GetBitStatus(LPC_ADC->ADGDR,SBIT_DONE)==0); /* wait till conversion completes */ adc_result = (LPC_ADC->ADGDR >> SBIT_RESULT) & 0xfff; /*Read the 12bit adc result*/ LCD_GoToLine(0); /* Go to First line of 2x16 LCD */ LCD_Printf("Adc0: %4d",adc_result); /* Display 4-digit adc result */ } }

Using Explore Embedded Libraries

In the above tutorial we discussed how to configure and use the inbuilt LPC1768 ADC.

Now we will see how to use the exploreEmbededd ADC libraries and interface POT,LDR and Temperature Sensor(LM35).

For this you have to include the adc.c/adc.h files. As the result will be displayed on the LCD, lcd.c/lcd.h also needs to be included.

Refer the LCD tutorial for interfacing the 2x16 lcd.

#include<lpc17xx.h> #include "lcd.h" //User defined LCD library which contains the lcd routines #include "delay.h" //User defined library which contains the delay routines #include "adc.h" void main() { uint16_t pot_value,ldr_value, temp_raw, temp_final; float voltage; SystemInit(); //Clock and PLL configuration /* Setup/Map the controller pins for LCD operation RS RW EN D0 D1 D2 D3 D4 D5 D6 D7*/ LCD_SetUp(P2_0,P2_1,P2_2,P1_20,P1_21,P1_22,P1_23,P1_24,P1_25,P1_26,P1_27); LCD_Init(2,16); /* Specify the LCD type(2x16) for initialization*/ ADC_Init(); /* Initialize the ADC */ while(1) { pot_value = ADC_GetAdcValue(0); /* Read pot value connect to AD0(P0_23) */ ldr_value = ADC_GetAdcValue(1); /* Read LDR value connect to AD1(P0_24) */ temp_raw = ADC_GetAdcValue(2); /* Read Temp value connect to AD2(P0_25) */ /*Converting the raw adc value to equivalent temperature with 3.3v as ADC reference using 12bit resolution. Step size of ADC= (3.3v/2^12)= 3.3/4096 = 0.0008056640625 = 0.0806mv For every degree celcius the Lm35 provides 10mv voltage change. 1 degree celcius = 10mv = 10mv/0.0806mv = 12.41 uinits Hence the Raw ADC value can be divided by 12.41 to get equivalent temp*/ temp_final = temp_raw/12.41; /* Vin = (Adc_value * REF)/ 2^12 */ voltage = (pot_value * 3.3)/ 4096.0; LCD_GoToLine(0); LCD_Printf("P:%4d %f",pot_value,voltage); LCD_Printf("\nL:%4d T:%4d",ldr_value,temp_final); } }